LCE Artificial Muscles

Creator: Ryan Lee

Supervisor: Peter Yeadon

Partner: Soft Matter Lab at the University of Rhode Island

This experiment seeks to learn how variation in the position of a heat source, creating inconsistency in the rate at which Liquid Crystal Elastomer (LCE) strips contract, will affect the movement of a ring attached to the LCE Strips.

Three equal length LCE Strips are connected to a rigid circular ring at equal angles from the center, with the radius of the circle equal to the activated (short) length of the strips, creating a downward angle when the strips are in their unactivated (long) length. When the strips are activated, they contract, causing the ring to be pulled upward, decreasing the angle of the strips. The same experiment is run with LCE Strips containing carbon black.

The experiment finds that when the heat source is a small heat gun, and the heat is directed towards only towards one strip, there is minimal effect on the movement of the ring: factors that influence this result include the size of the heated air blown onto the LCE, and inconsistency in the experiment construction causing certain strips to be more prone to react to the heat to begin with.

Findings

-

Clear LCE sample snapped at 40%, 35%, 30%, 20% strain when attempting to cure; succeeded at 10%

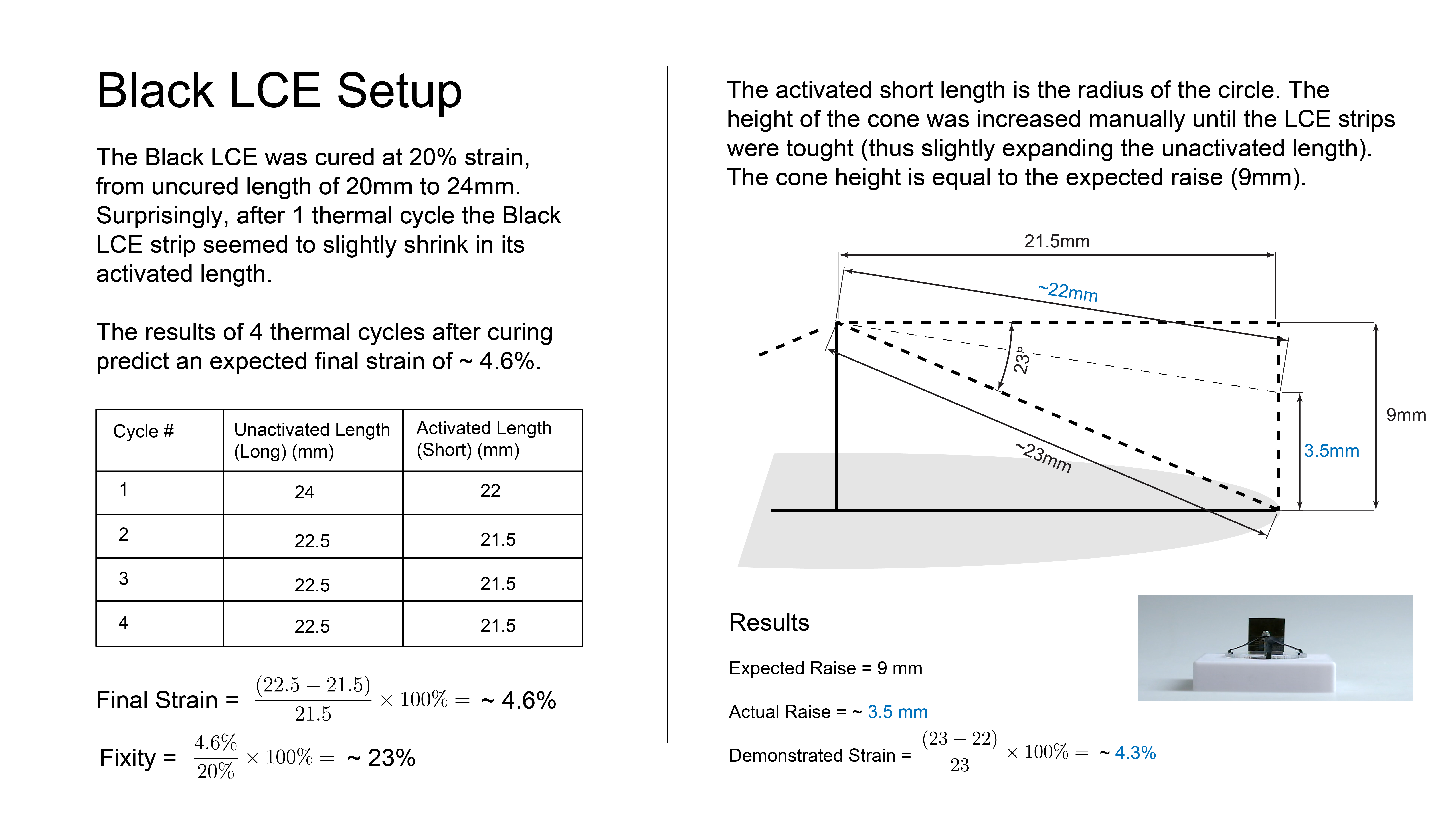

- Carbon Black LCE sample snapped at 30% strain when attempting to cure; succeed at 20%

-

Clear LCE: after 3 thermal cycles a final strain of 7% was achieved, making a fixity of ~ 70%

- Carbon Black LCE: after 4 thermal cycles a final strain of 4.6% was achieved, making a fixity of ~ 23%

-

Strategies for heating to prevent snapping included adding a silicone pad “buffer” between rigid clamp edge and LCE to decrease the acute edge force on the LCE surface

-

Strategies for activating the cured LCE strips included visually observing the surface finish of the LCE (becomes obviously more shiny when activated), which was found to be a more effective indicator of activation rather than monitoring temperature

Previous Next

Back︎︎︎