OPTI : Hot, but not Too Hot

Creator: Matthew Derry

Supervisor: Peter Yeadon

This project investigates a responsive thermal regulation method for vacuum thermoses, using shape memory alloys and thermochromic coatings. In their current form, vacuum thermoses are exceptionally effective at maintaining the temperature of their hot contents. However, if a drink starts off too hot, then it is kept too hot for many hours.

The design of OPTI solves this problem by utilizing a lid that contains nitinol shape memory alloy (SMA) springs to manage thermal energy transfer between the thermos and its environment.

The design of OPTI solves this problem by utilizing a lid that contains nitinol shape memory alloy (SMA) springs to manage thermal energy transfer between the thermos and its environment.

When the compressed SMA springs are heated above their transition temperature of >75ºC (>170ºF), the heat causes the springs to expand to touch the exterior of the lid, creating a thermal bridge within the lid, and allowing heat to escape to the surroundings.

Once the internal temperature drops below the transition temperature, the SMA springs contract again, breaking the thermal bridge, and stopping heat transfer through the lid.

Once the internal temperature drops below the transition temperature, the SMA springs contract again, breaking the thermal bridge, and stopping heat transfer through the lid.

By automatically transitioning between these two states, OPTI’s lid regulates the internal temperature of the thermos, initially cooling the liquid, and then stopping that flow of heat in order to maintain the temperature for hours.

The heat retention method in this design uses the same principles as most thermoses on the market today. By surrounding the contents with a vacuum, the thermos all but eliminates heat transfer to the surrounding environment. OPTI’s key differentiator is within the design of the lid.

Inside is a vacuum cavity that contains a copper plate which can move up and down, regulated by the expansion of the SMA springs. A silicon-based elastic foam with high thermal conductivity connects the copper plate to the base of the lid. This foam works both as a bias spring, to reset the system when the nitinol springs are not activated, and as a means to conduct heat from the bottom of the lid.

The heat retention method in this design uses the same principles as most thermoses on the market today. By surrounding the contents with a vacuum, the thermos all but eliminates heat transfer to the surrounding environment. OPTI’s key differentiator is within the design of the lid.

Inside is a vacuum cavity that contains a copper plate which can move up and down, regulated by the expansion of the SMA springs. A silicon-based elastic foam with high thermal conductivity connects the copper plate to the base of the lid. This foam works both as a bias spring, to reset the system when the nitinol springs are not activated, and as a means to conduct heat from the bottom of the lid.

When the SMA springs are activated, the moving copper plate is pressed up against the top of the lid, completing the thermal bridge between the contents of the thermos and the surrounding environment. When the SMA springs deactivate, the retraction of the copper plate restores the vacuum gap, breaking the thermal bridge and stopping the heat transfer. On both the bottom and top of the lid are copper heat sinks, these act to draw heat from the liquid inside and to dissipate heat to the surroundings respectively.

You can see the SMA springs and elastomer foam working in the demonstration prototype, below. The first image, below, shows the prototype warming over boiling water, expanding to create a thermal bridge. The second image, below, shows the prototype cooling, and a thermal break being established.

You can see the SMA springs and elastomer foam working in the demonstration prototype, below. The first image, below, shows the prototype warming over boiling water, expanding to create a thermal bridge. The second image, below, shows the prototype cooling, and a thermal break being established.

Even though heat transfer will stop as soon as the drink is safe to consume, the user needs to know what phase the system is in. This information is communicated by using a thermochromic leuco dye ink on the top of the lid, which transitions from opaque black to transparent at high temperature. The thermochromic sensor and warning graphic is shown above.

As heat is being drawn through the lid, to cool the contents inside, the lid's top copper surface will heat up and the leuco dye layer will turn transparent, revealing a warning message that both the contents and the lid surface are hot. Then, once the SMAs initiate a thermal break and the heat transfer stops, the top copper surface will quickly cool, allowing the leuco dye to reappear with a message that the drink is ready to enjoy.

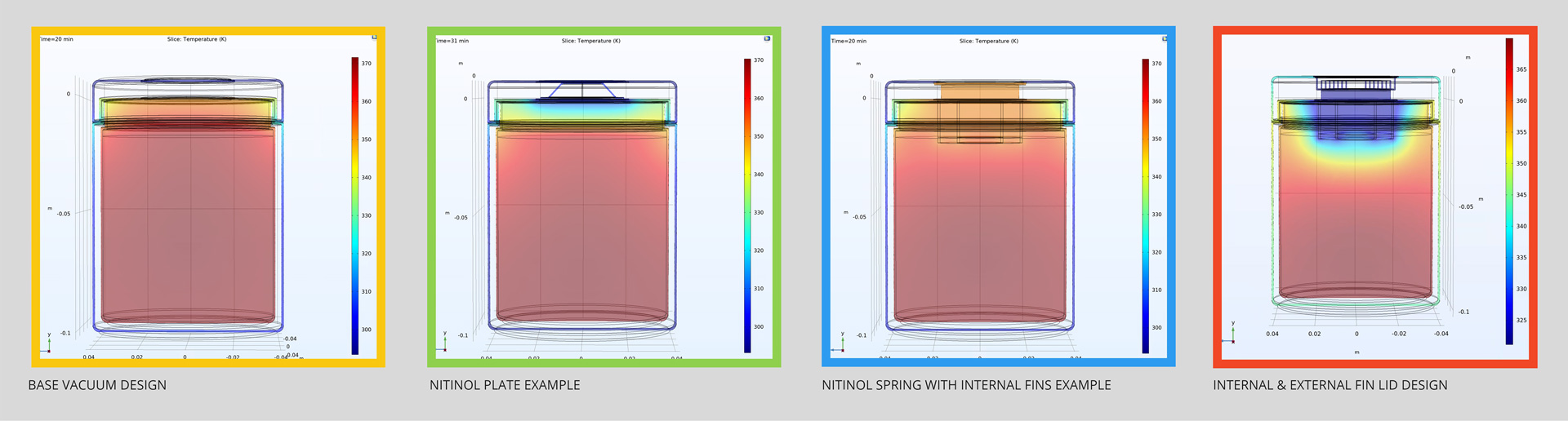

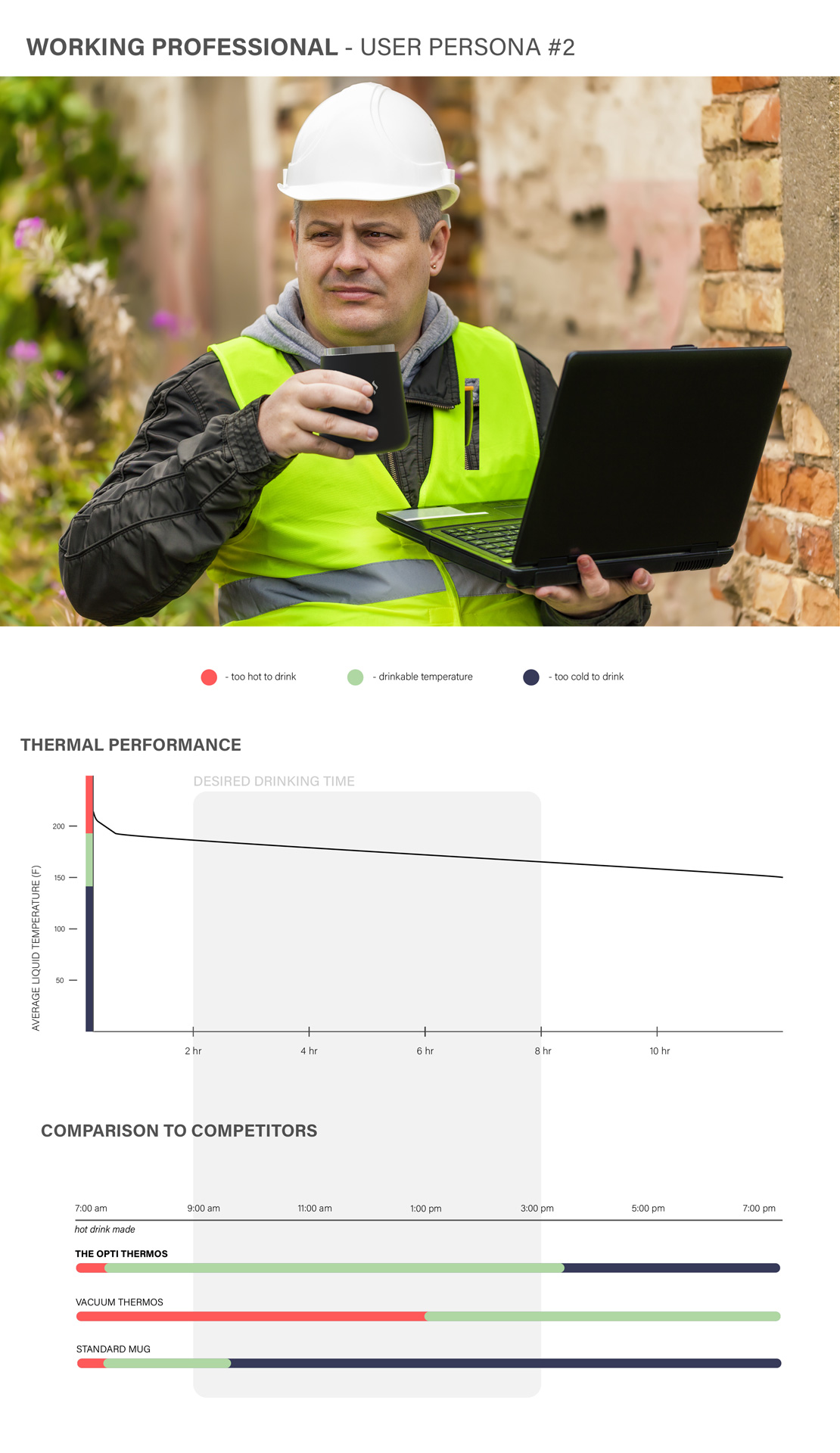

Thermal studies performed with COMSOL Multiphysics helped to test and reinforce the benefits of the product. The design is able to drop the average liquid temperature from 93°C to a safe 76-79ºC in roughly 25 minutes, 1400% faster than a standard vacuum thermos. Once the correct temperature is achieved, the simulation shows there is a 9 hour window before the temperature drops out of the ‘enjoyable to drink’ range (below 60ºC).

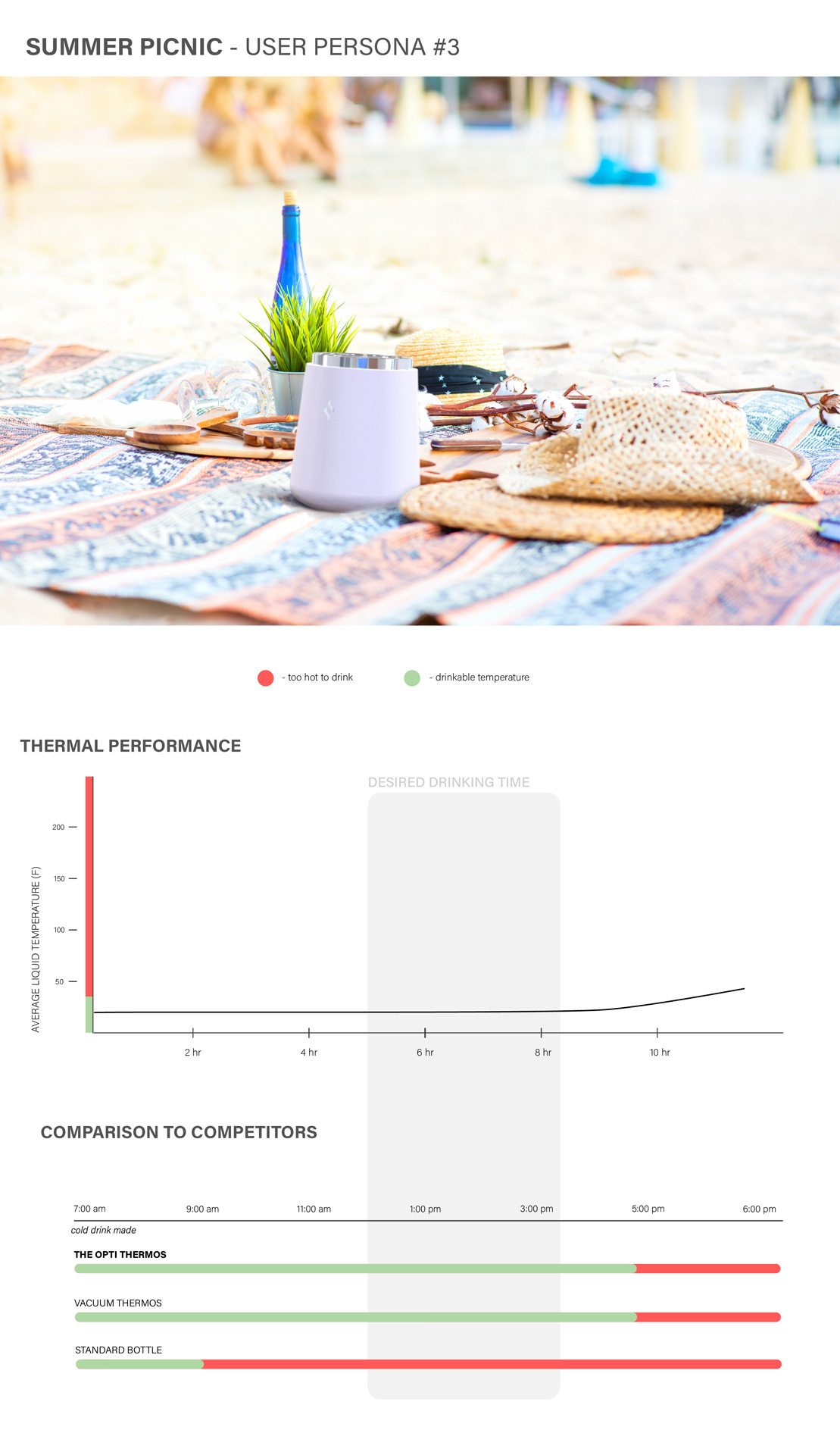

Another key benefit is the ability of the system to still perform at low temperatures. For a cold drink, the SMA springs would not be activated, thus the system would still mitigate heat transfer and retain the cold temperature of the drink. This means that regardless of the starting temperature, the OPTI thermos will perform as well as, if not substantially better than, vacuum thermoses used today.

Another key benefit is the ability of the system to still perform at low temperatures. For a cold drink, the SMA springs would not be activated, thus the system would still mitigate heat transfer and retain the cold temperature of the drink. This means that regardless of the starting temperature, the OPTI thermos will perform as well as, if not substantially better than, vacuum thermoses used today.

The mechanism involved is not particularly complicated, thus, the cost of the OPTI thermos would not be substantially greater than a baseline vacuum thermos. This further expands the use-cases and the possible functionality of the thermos.

OPTI can be used just the same as any other thermos with the added benefit of regulating the temperature of boiling hot drinks (and soups). The final lid design proposes a full enclosed system, so that all components are dishwasher safe, durable, and reliable. With the SMA smart materials fully-enclosed and able to withstand thousands of cycles, OPTI should never need maintenance and should work flawlessly for a lifetime.

Three envisioned user personae are provided below.

OPTI can be used just the same as any other thermos with the added benefit of regulating the temperature of boiling hot drinks (and soups). The final lid design proposes a full enclosed system, so that all components are dishwasher safe, durable, and reliable. With the SMA smart materials fully-enclosed and able to withstand thousands of cycles, OPTI should never need maintenance and should work flawlessly for a lifetime.

Three envisioned user personae are provided below.

Previous Next

Back︎︎︎