RE:PACK.FLUX

Creator: Kathryn Chen

Supervisor: Peter Yeadon

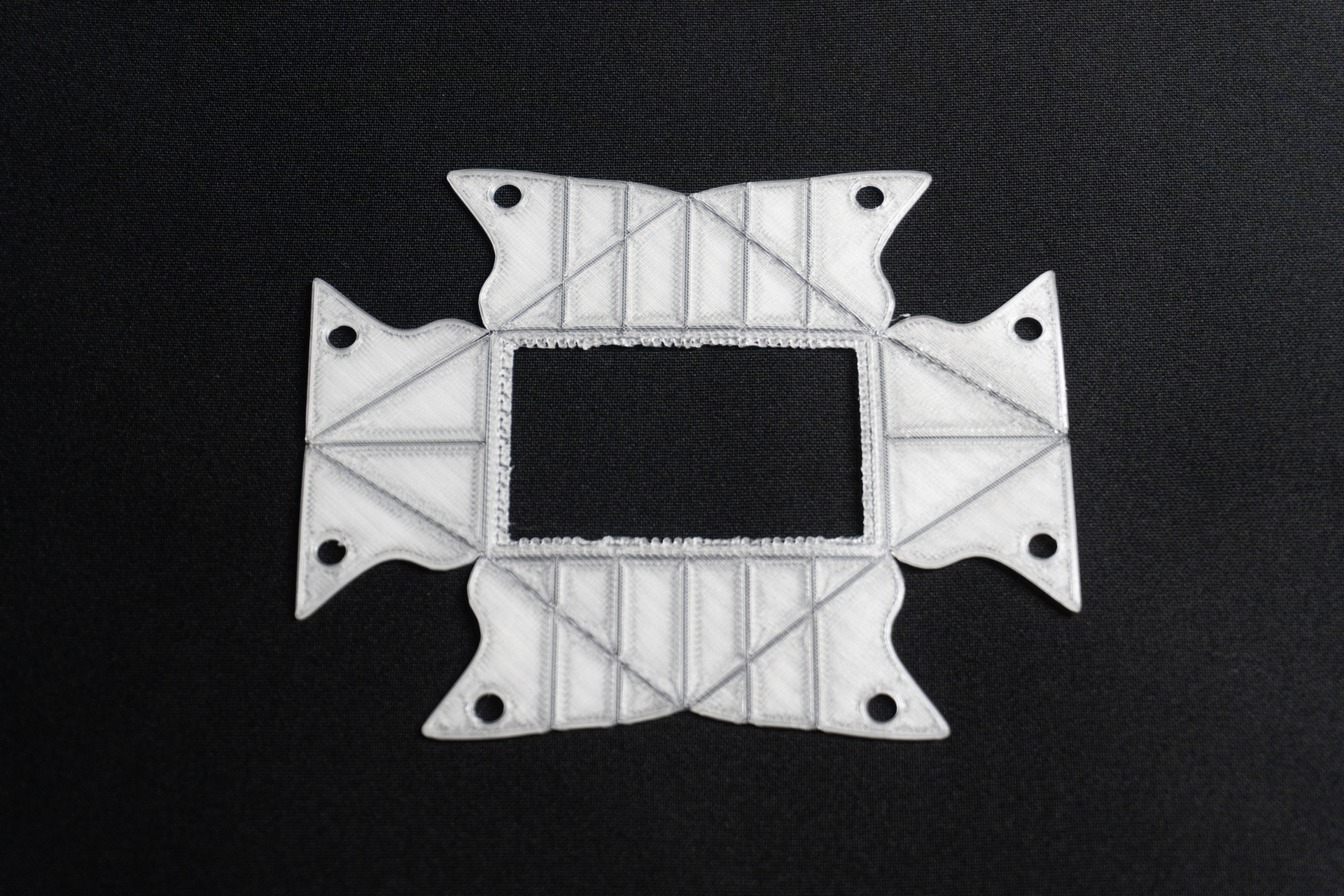

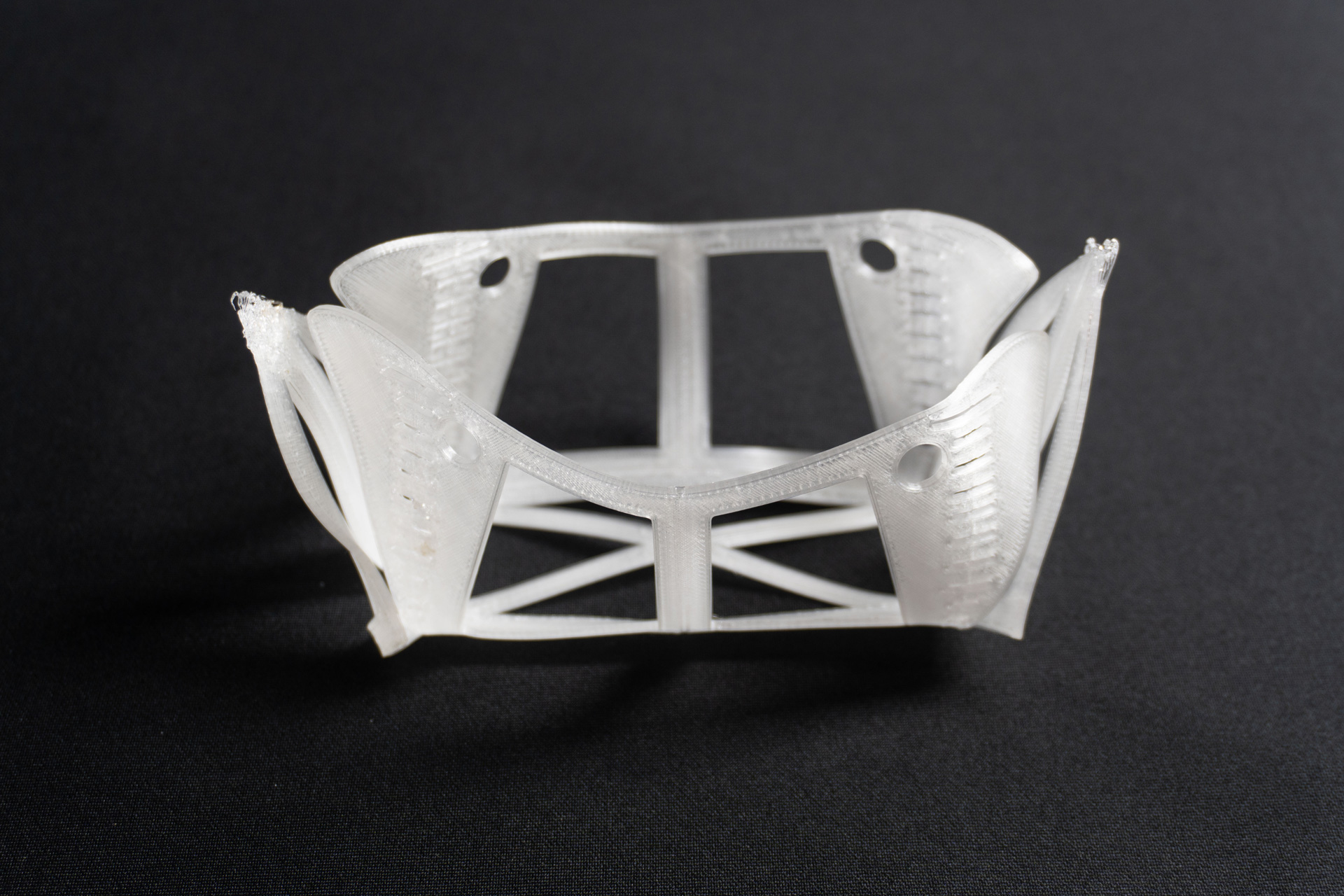

This study focused on creating a transformative handbag that is shipped flat, but is then heated in a retail store to become a three-dimensional bag. The core material technology is a thermoresponsive shape memory polymer that changes shape at approximately 40°C, using accessible tools, such as a hair dryer or clothing steamer. The design features clearly marked folding lines that guide the consumer through the transformation process, making it easy and suitable for at-home activation as well.

The concept addresses today’s tariff and shipping cost increases by allowing multiple units to be stacked and shipped compactly, significantly reducing transportation expenses and environmental impact. Regarding tariffs, the product is merely a flat sheet of material when it enters the country, and is only later transformed or “made” into a handbag at the store, or at home.

The project focused on three core goals:

1. ship flat, transform later

2. in-store heat activation

3. cost-effective and sustainable design

The handbag is built around 3D-printed sheets of shape memory polymer, which serve as the bag’s skeleton. These sheets have perforations for sewing and folding. To complement the structure, neoprene was selected for the bottom — chosen for its thickness and flexibility — and power mesh was selected for the outer skin. The power mesh offers transparency, allowing visibility of the folding lines and internal structure, while providing the stretch needed to move with the form as it transforms.

The project represents an innovative approach to merging fashion, functionality, and material science, resulting in a product that is both efficient to ship and engaging for users to assemble and activate.

Previous Next

Back︎︎︎