The Grabber

Creator: Lisa Abuaf

Supervisor: Peter Yeadon

This study explores a simpler, cheaper, and more versatile robotic grabbing mechanism that could replace most current grabbing mechanisms. Almost all grabbing mechanisms on robotic arms have a form that's similar to the human hand, and each one can only grab particular objects. In contrast, this new grabber is made out of a flexible material that enables it to grab onto distinct shapes, objects, and sizes.

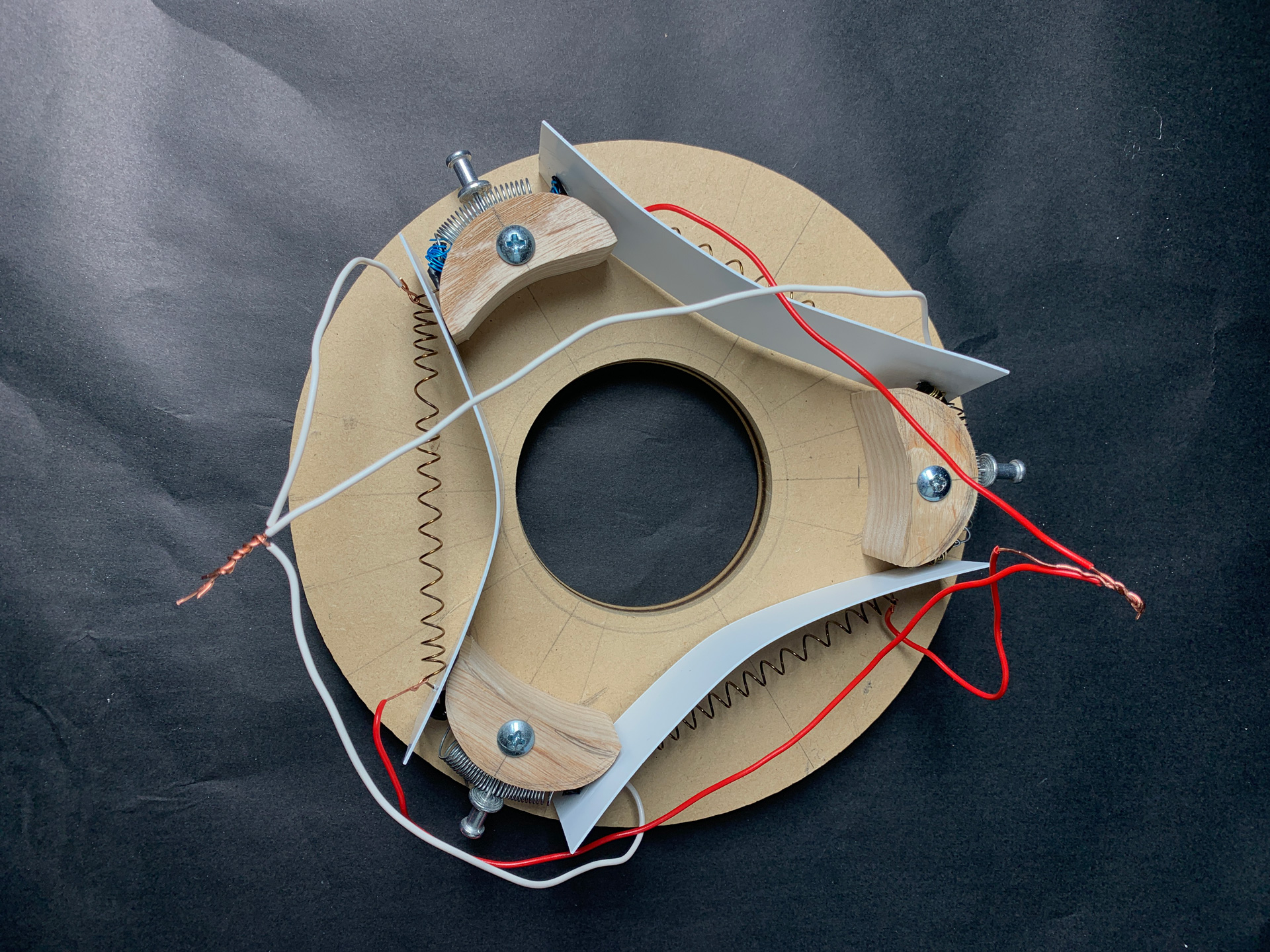

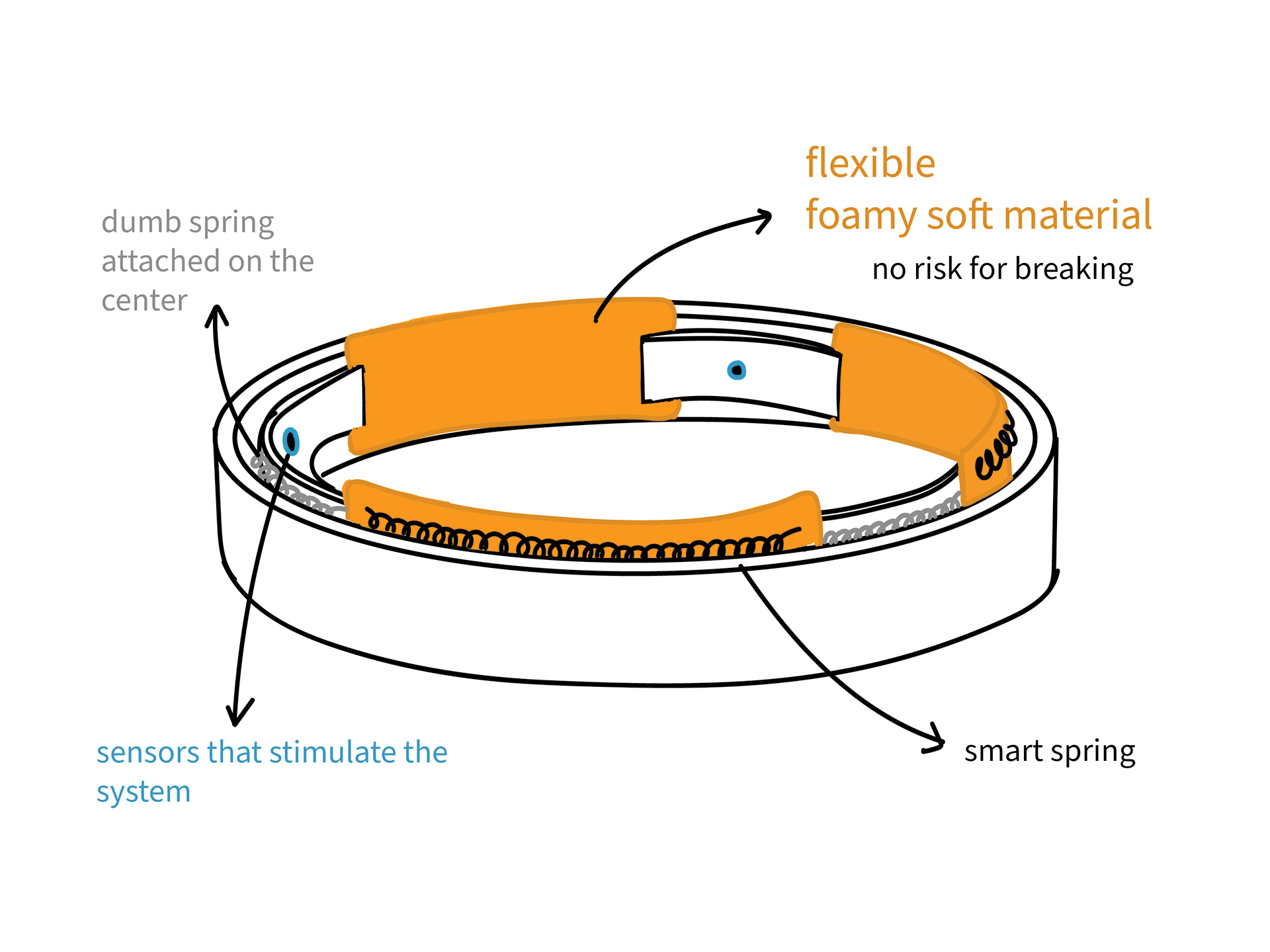

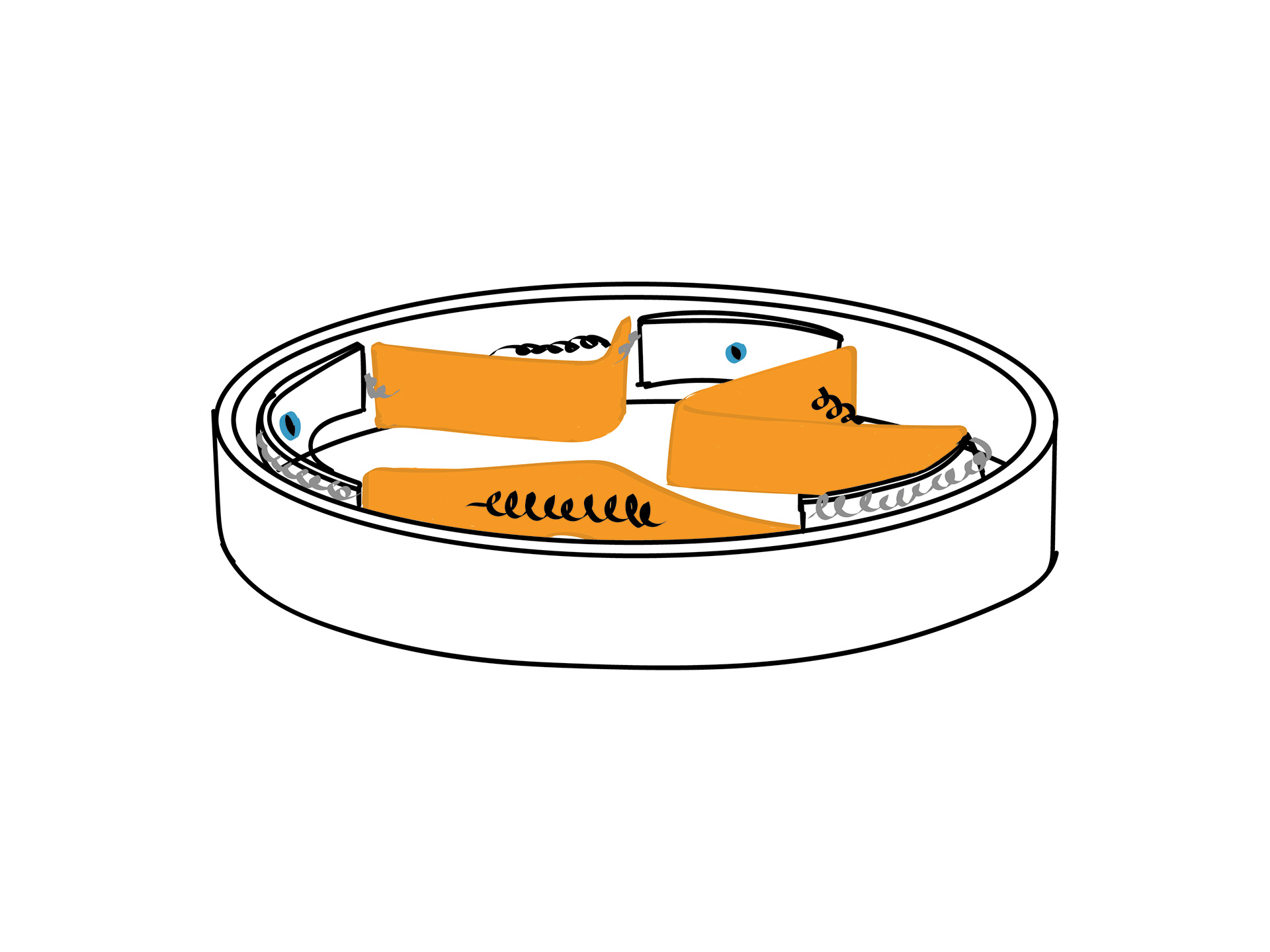

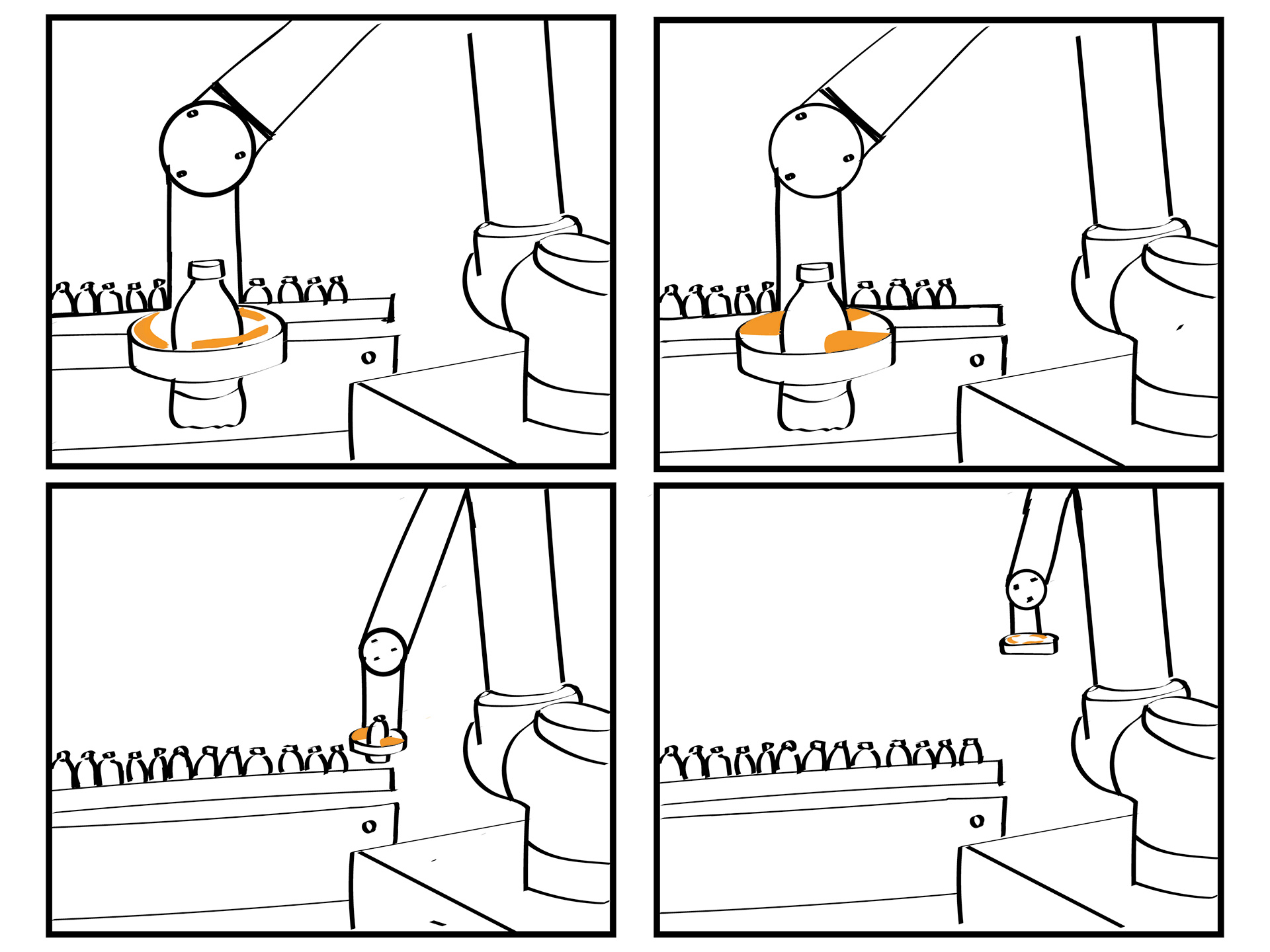

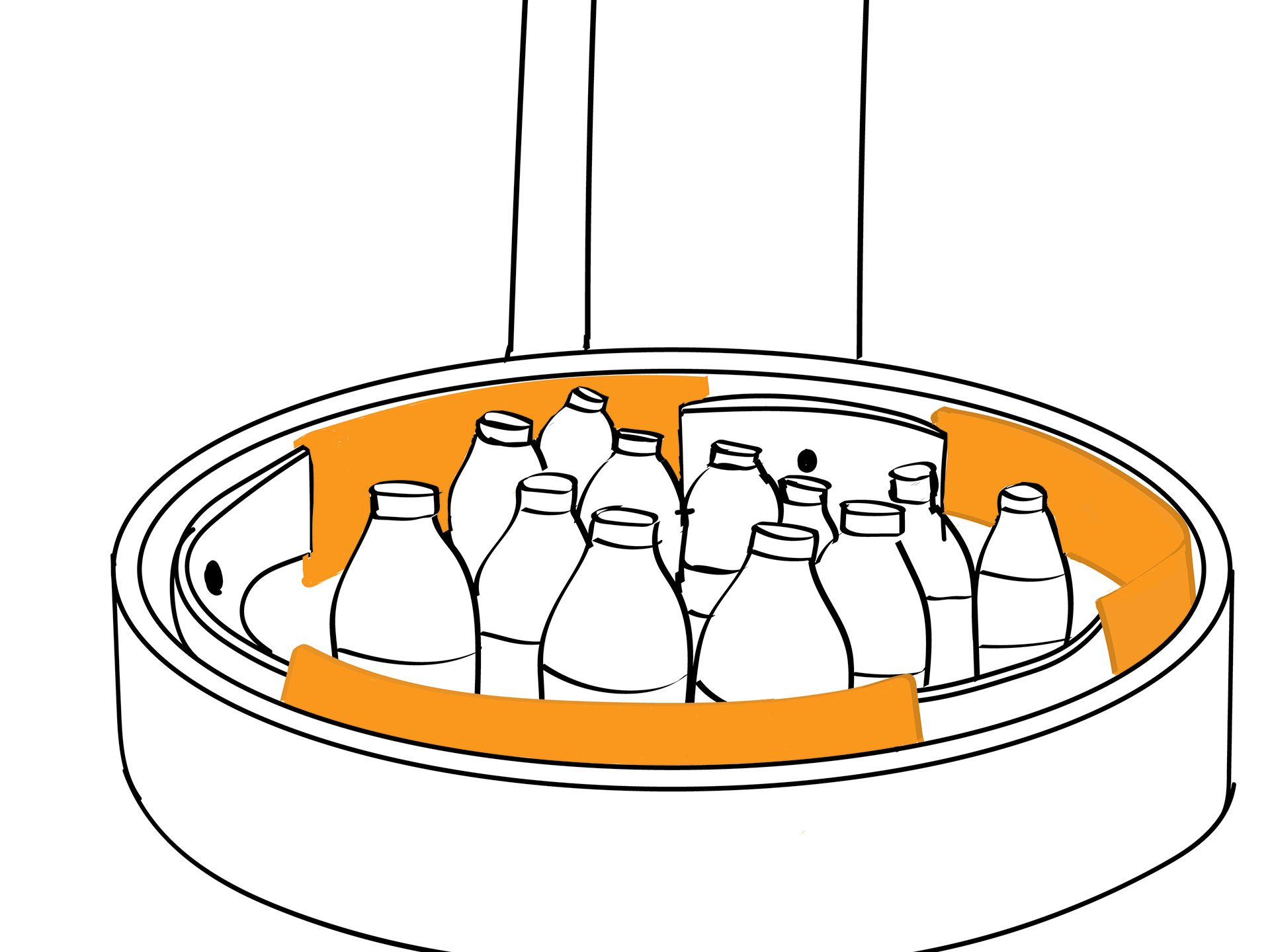

In particular, this study focuses on developing a grabber for use in plastic bottle production. The grabber works by wrapping around the object and forming a grip. This allows the grabber to transport a single bottle, as well as multiple bottles if the mechanism is scaled up. It consists of six parts and six springs, three of which are shape memory alloy (SMA) springs.

The SMA springs react to heat that's generated via electrical resistance, contracting and causing the grabber pieces to bend and move towards the middle to complete the grabbing action. As power is cut and they cool, the three counterforce springs cause the SMA springs to expand and the grabbers to straighten, resulting in the release of the object.

The Grabber could be used by robotic arms to replace many existing grabbing mechanisms, and would easily mounted or demounted. And, although this study focused on managing bottles, the mechanisms would work well for grabbing any range of cylinders and other forms.

Previous Next

Back︎︎︎